MultiMechanics, an Omaha-based developer of composite modeling and simulation software, has announced a strategic technology partnership with Fortify, a Boston-based additive manufacturing company specialized in composite material systems.

The goal of the collaboration is to improve the predictability of composite 3D printing.

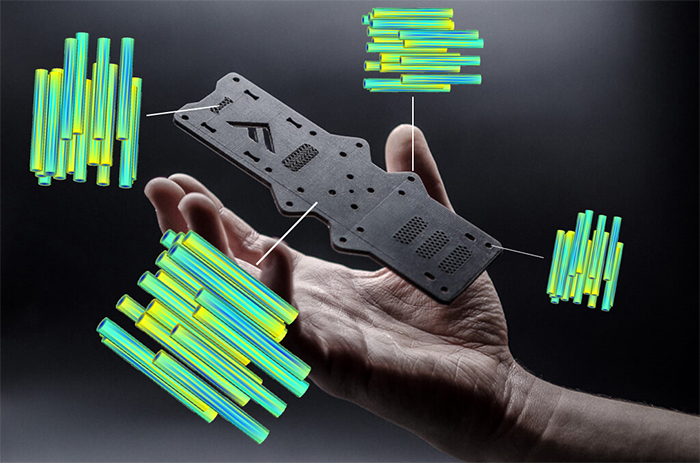

As part of the partnership, Fortify will use MultiMechanics’ flagship product, MultiMech, to predict the structural integrity of printed parts before they are printed, and to help optimize the design by controlling the fiber orientation throughout the structure.

“We see a definite need for better predictability in 3D printing, and we believe that our application poses a unique use case for the MultiMechanics software,” said Fortify CEO Josh Martin. “The resulting printed parts take full advantage of the strength-to-weight benefits of composite materials to a degree of resolution and complexity not possible before.”

Many companies involved in the 3D printing of composites struggle to determine how their printed part will behave. With the Fortify print analysis software and Fluxprint printing capabilities, MultiMech will act as a tool to provide the required feedback for closed-loop iterative design of composite parts with optimized fiber orientation. This collaboration will enable users to optimize the design and manufacturing of parts to fit specific applications.

“We have a few exciting projects in the pipeline that will benefit from the use of MultiMech, including end-use components for industrial UAVs, and injection molding tools,” Martin said. “We are excited to partner with MultiMechanics to push the 3D printing industry forward.”

As the two startups continue to expand, MultiMechanics and Fortify plan to integrate the MultiMech API in Fortify printers. The simulation capabilities of MultiMechanics would then be available to users of Fortify, giving engineers full control over the 3D printing process, from design and testing to final production.

“We are excited to partner with Fortify because both companies offer users the ability to control microstructural design at every single point of a product, MultiMechanics CEO Leandro Castro said. “Fortify allows that in the real world, while MultiMechanics enables that virtually. This strong synergy removes design constraints to create truly optimized parts.”

The partnership comes one year after MultiMechanics announced a capital raise of nearly $2 million. Among the goals of the investment was to expand the company’s presence in the commercial marketplace, which the Fortify partnership does.

“This is the first time we’re partnering with a company that is actually developing 3D printing technology,” Castro said. It gives designers a greater level of control and customization.”

MultiMechanics was founded in 2010 by Castro and Flavio Souza, both Brazilian natives who met in Lincoln through a collaborative program between the Federal University of Ceara in Brazil and the College of Engineering at the University of Nebraska-Lincoln.

––

Rod Armstrong is Vice President of Strategic Partnerships for AIM in Lincoln, Nebraska. He is a regular contributor to Silicon Prairie News.