University Medical Devices (UMD), a medical device startup in Omaha, has released its first product nationwide. MicroWash is a nasal specimen collection device designed for use by health care providers. The innovation represents a culmination of research and prototyping by University of Nebraska Medical Center (UNMC) researchers in collaboration with tech transfer offices, entrepreneurs and manufacturers in Nebraska.

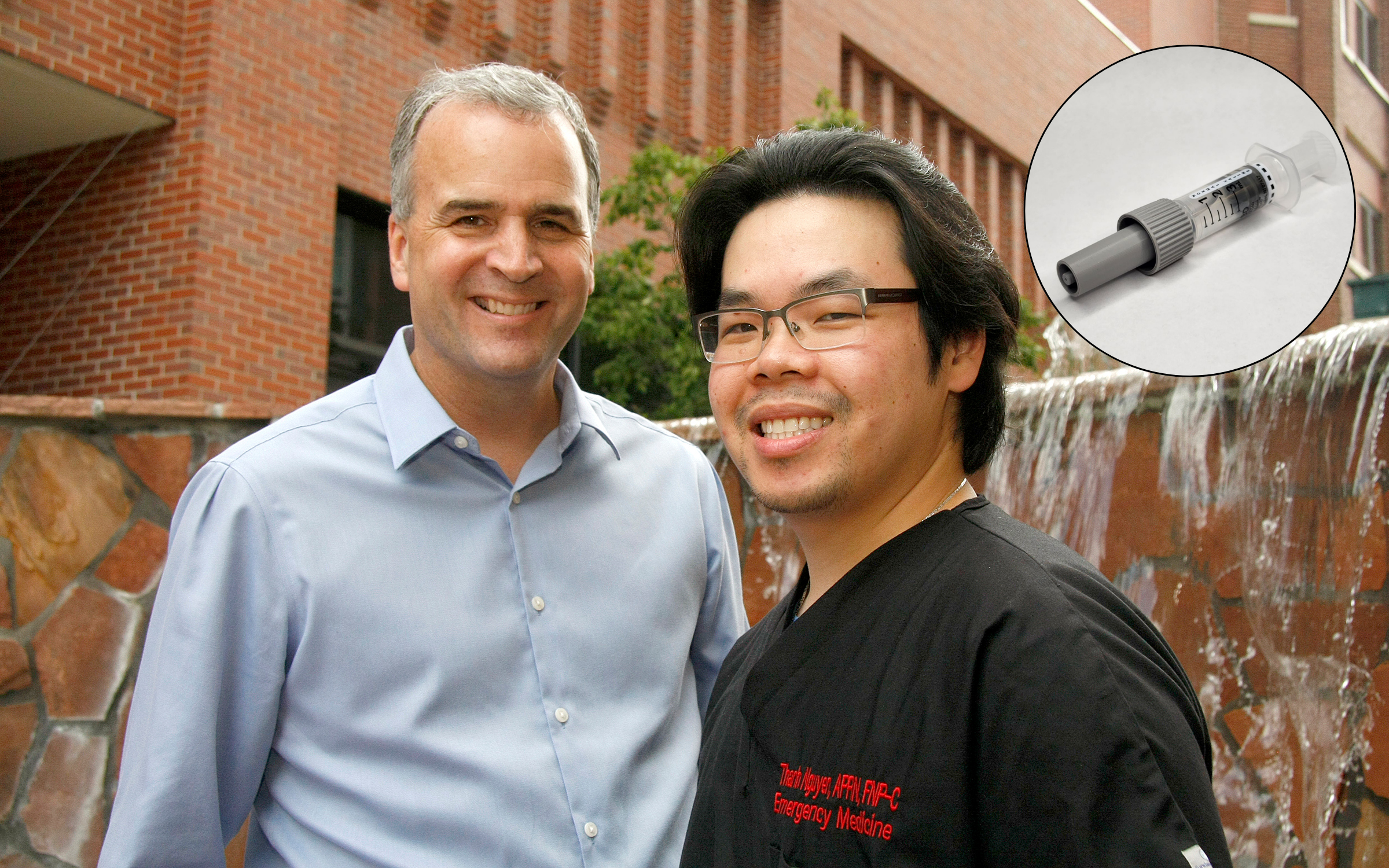

UMD CTO Thanh Nguyen, Ph.D., said the origins of MicroWash came from the “thinking on the fly mentality” of UNMC medical professionals on the frontlines of the COVID pandemic. The product was invented as a more standardized way to gather samples while keeping medical staff safe. Nguyen and his UNMC colleague Michael Wadman, M.D., workshopped the idea of splashing enough fluid in a patient’s nose to collect debris for testing.

Nguyen said while developing MicroWash, the team was able to successfully navigate some of the typical early risks associated with the prototyping phase by leveraging a combination of startup support organizations and grants. The team worked with UNeMed and UNeTech and received federal grants designated to support COVID response efforts. Nguyen said additional resources came from the National Institutes of Health (NIH) and the Nebraska Department of Economic Development.

“All of our academic work tends to move towards this path of publication, and then if that particular topic is robust enough, you just keep researching it,” said Nguyen. “As academics, we don’t really know what the next steps are after that … how much work it is to take it to the next step.”

Nguyen said he and fellow researchers turned to the expertise of those more involved in the startup community to grow the solution into a company and build a team. Members of UMD leadership participated in the 2022 NMotion Accelerator and raised a $1.6M seed round in 2024 to ready the MicroWash for market.

UNeTech Associate Director Joe Runge said his organization began working with Nguyen and the MicroWash team at its early stages and connected them with prototype manufacturing capabilities at Metro Community College through initiatives including the Omaha Medical Technology Pipeline and UNeTech Deploy!

Nguyen said he and his team were then able to connect with local manufacturers Major Plastics and RD Tool and Engineering to finalize the injection molding necessary for MicroWash’s unique design. Preparing for national distribution via medical supply distributor McKesson with tariff increases looming in the background, he said the lower costs and ability to communicate directly with manufacturers influenced UMD to produce MicroWash in the U.S. — with a majority of the work done in Omaha.

Runge said UNeTech’s services for university-affiliated startups fluctuate depending on the funds and personnel available and needs expressed by the community. While the organization has transitioned to primarily focus on software-based solutions in response to local investors’ interests in these quicker-to-scale business models, he said there is still an established infrastructure in Nebraska for future physical device production.

“To be able to take the CEO and be able to make those introductions from the jump, that’s essentially several years of work that they now have jumped over,” said Runge. “I think it’s because of the great relationships UMD built and the great work MicroWash did in these efforts.”

Nguyen said his and Wadman’s experience with getting MicroWash market-ready enabled the two to move forward quickly and more confidently with the development of another MedTech startup they’re partnering with RD Tool and Engineering on called HemaGlobal. This separate Nebraska company focuses on an innovation for blood smears.

As for UMD, Nguyen said the company will shift focus to its next product once MicroWash production becomes a “well-oiled machine.”